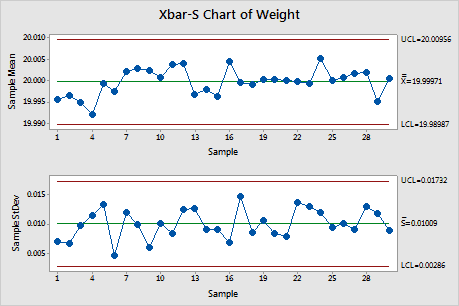

When the process starts to go out of control, it should produce alarms when compared to the control limits calculated when the process was in control. Instead, as you move forward, you apply the previously calculated control limits to the new sampled data. Because once the process goes out of control, you will be incorporating these new, out of control values, into the control limit calculations, which will widen the control limits. What you don’t want to do is constantly recalculate control limits based on current data. The control limit lines and values displayed in the chart are a result these calculations. Therefore it is a suitable source of data to calculate the UCL, LCL and Target control limits. The initial chart represents a sample run where the process is considered to be in control. The LCL value for Individual-Range charts is always 0.0. That is where the 3.267 comes from in final reduction of the UCL formula above. So all you need to consider is the \()\), a sample subgroups size of 2 is used in the D4 lookup, resulting in the value of 3.267. The formulas for Individual-Range charts are listed below.Įach sample interval has only one value, for a subgroup sample size of one. These limits are calculated based on monitoring and sampling the process when it is running while “in control”. The initial setup of the chart typically involves establishing standardized control UCL (Upper Control Limit) and LCL (Lower Control Limit), and Target (Centerline) values, for both the Primary (XBar) and Secondary (Range) charts. Better to just go with just one sample at a time. Some processes will always result in values within of subgroup that are extremely close in value, when compared to the values from different batches or times.Which chart you use depends on how you want the operators to interpret the chart. But the Individual-Range chart will result in fixed control limits. The XBar-Sigma chart using variable sample size will produce control limits that vary from sample interval to sample interval. You can either go with the XBar-Sigma chart using variable sample size, or an Individual-Range chart using one sample per sample interval. You are sampling the production output at some fraction of total output, but due to the nature of the manufacturing process, the sample subgroup size is not constant.You are measuring every unit of production output, so there is no reason to organize the sample data into subgroups.Some of the reasons where this might be the case are: You use an an I-R chart if your sample subgroup size is one. Superimposed control lines indicate whether or not the process being monitored is in or out of statistical control. The look-back of one sample interval when calculating the Range value for the Range chart is why it also called a Moving Range chart. The Individuals part of the chart plots the single sample for each sample interval, and the Range part of the chart monitors the difference between the sample in the current sample interval, and the sample in the previous sample interval. The Individual-Range chart monitors the trend of a critical process variable over time using a statistical sampling method that results in a single sample per sample interval. The Individual-Range chart is one of several chart types which fall under the general category known as Shewhart Variable Control Charts, which is a general grouping of SPC chart types that work with quality data expressed as numeric values (i.e. The data used in the chart is pulled from the Individual-Range chart example, Table 6-6, in the textbook Introduction to Statistical Quality Control 7th Edition, by Douglas Montgomery. The example below shows a typical Individual-Range chart. The top graph is the Individuals chart, and the bottom graph is Range chart. A typical Individual-Range chart consists of two graphs displayed one above the other. You will find the chart listed under may different names, including: Individual-Range, I-R, I-MR, X-R, X-MR, Individual-Moving Range, and Control Chart for Individual Measurements. The Individual-Range pair of charts are among the most commonly used charts in SPC.

0 kommentar(er)

0 kommentar(er)